We specialize in advanced PLC development, offering robust support to optimize your automation needs. Trust us for cutting-edge solutions that enhance efficiency and reliability in your operations.

At SNBB we collaborate with industry-leading hardware providers to ensure cutting-edge technology for our solutions. Our partnerships enable us to integrate the latest and most reliable hardware into our offerings, enhancing performance and customer experience. This synergy between top-tier hardware and our innovative approaches sets us apart in delivering exceptional value and results.

Standard PLCs are used in a wide range of industries for basic automation tasks. They are ideal for controlling machinery, assembly lines, and process control, where consistent, reliable operations are critical. Their standardization ensures easy integration and compatibility with various systems and equipment.

Safety PLCs are crucial in environments where there is a high risk of accidents or in processes that require strict adherence to safety regulations. They are used in sectors like manufacturing, chemical processing, and power generation to ensure safe operations, preventing accidents and protecting both equipment and personnel.

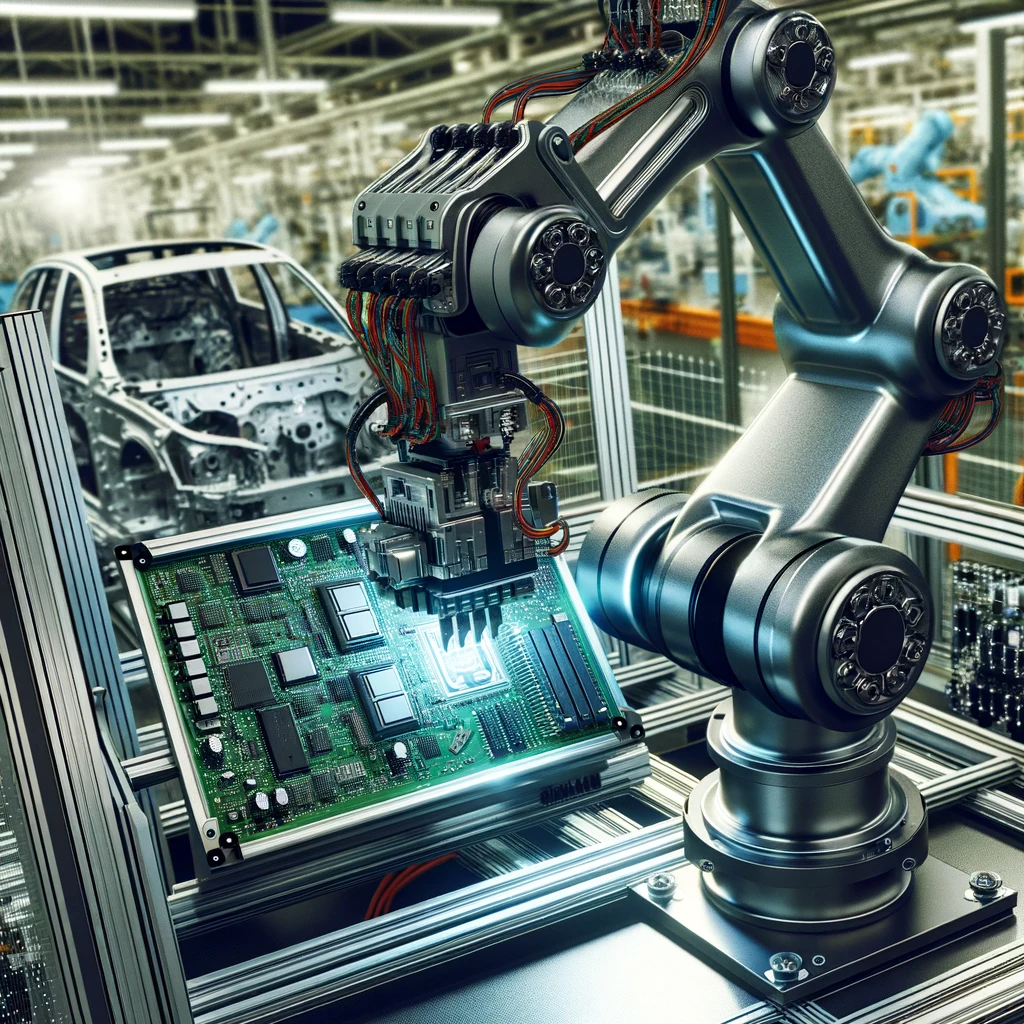

Servo PLCs are employed in applications requiring high precision and control, such as robotics, CNC machines, and conveyor systems. They excel in tasks that need accurate positioning, speed control, and smooth motion, making them ideal for complex automation systems in manufacturing and packaging industries.

Vision PLCs are used in quality control, inspection, and guidance systems. They are essential in industries like automotive, electronics, and pharmaceuticals, where they help in defect detection, part identification, and guiding robotic systems for intricate tasks, thereby enhancing accuracy and efficiency.

SCADA-related PLCs are used for monitoring and controlling large-scale industrial processes like water treatment, energy distribution, and large manufacturing plants. They enable remote monitoring, data collection, and control of various site operations, ensuring efficient process management, reduced downtime, and improved decision-making.

I've witnessed firsthand the transformative impact of PLC development on our operational efficiency. The ability to access and monitor live data has been a game-changer. We can now track every aspect of our production process in real-time, identifying and addressing issues immediately, which was not possible before. This enhanced visibility has led to a significant increase in productivity and a reduction in downtime. The PLC system's precision and reliability have not only optimized our workflows but also bolstered our commitment to quality and efficiency.

"The introduction of operator monitoring solutions by Company A has revolutionized how we manage our workforce and operations. Their system's intuitive design and real-time monitoring capabilities have significantly boosted our team's performance and accountability. This partnership has been instrumental in enhancing our operational efficiency and maintaining high standards of productivity."